Product Overview

Our advanced natural gas burner for ceramic kilns is engineered to revolutionize energy efficiency in ceramic firing processes. By integrating intelligent pre-mixing technology and customizable combustion profiles, this burner reduces natural gas consumption by 4–11% or more while maintaining precise temperature control and product quality.

Energy-Saving Principles

1. Pre-Mixing of Combustion Air and Natural Gas

Traditional burners inject fuel and air separately into the kiln, relying on diffusion for combustion. This method often leads to incomplete fuel oxidation, wasted heat, and excessive emissions.

Our burner solves this challenge through pre-mixing technology:

- Uniform Combustion: Natural gas and combustion air are thoroughly mixed *before* entering the kiln chamber, ensuring a homogeneous mixture.

- Faster Ignition & Stable Flame: Pre-mixed fuel achieves near-stoichiometric combustion, minimizing unburned fuel residues and reducing heat loss.

- Lower Peak Temperatures: Even heat distribution prevents localized overheating, protecting kiln linings and reducing energy waste.

2. Customizable Combustion Profiles for Daily Kiln Conditions

No two kilns operate identically. Variations in firing schedules, product types, and atmospheric requirements (oxidizing/reducing) demand adaptable solutions.

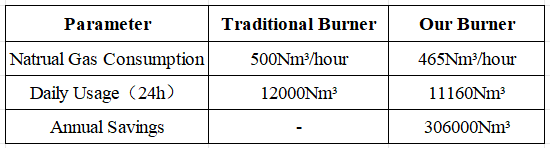

Energy Savings Demonstration

Case Study: A ceramic tile factory operating a 100-meter tunnel kiln at 1,250°C.

Calculations:

- Hourly Savings: 500 – 465 = 35 Nm³/hour (7% reduction)

- Annual Savings: 35 Nm³/h × 24h × 365d = 306,000 Nm³

- Cost Savings: At $0.3/Nm³, annual savings = $91,800

Result: 7% energy reduction achieved with no compromise on output quality. Trials show efficiency gains ranging from 4% (low-variability kilns) to 11% (multi-profile kilns).

Why Choose Our Burner?

- Proven ROI: Payback period under 12 months via fuel savings.

- Emission Compliance: Cleaner combustion cuts NOx/CO by 15–20%.

- Smart Integration: Compatible with existing kiln control systems.

Conclusion

By combining precision pre-mixing technology with adaptive combustion profiles, our natural gas burner delivers measurable, sustainable energy savings for ceramic manufacturers. Contact us to calculate your kiln’s customized savings potential!

Newpearl report.pdf

Newpearl report.pdf

*Innovate your firing process. Reduce costs. Protect the planet.*